Lignosulfonates

The origin of lignin

Lignin is one of the natural polymers found in wood and accounts for 33% of the weight. It is even the second most common organic substance in the world after cellulose. The separation of Lignosulfonates from the other major component in wood, cellulose, takes place through a sulfonation process where wood is cooked in a chemical solution under specific pressure and temperature conditions. As a result, the lignin is separated. The cellulose remains unaltered and is used in the pulp and paper production industry.

Our lignosulfonates

At Lignostar we focus mainly on four different lignosulfonates, sodium lignosulfonates, magnesium lignosulfonates, calcium lignosulfonates, and ammonium lignosulfonates. The LignoStar range of lignosulfonates includes two types, StarLig, for chemical applications, and StarBond, for zootechnical applications. These products are available in either powder or liquid form to meet requirements for all types of use. The binding properties of StarBond lignosulfonates make them one of the best additives for pelleting animal feed and other zootechnical applications.

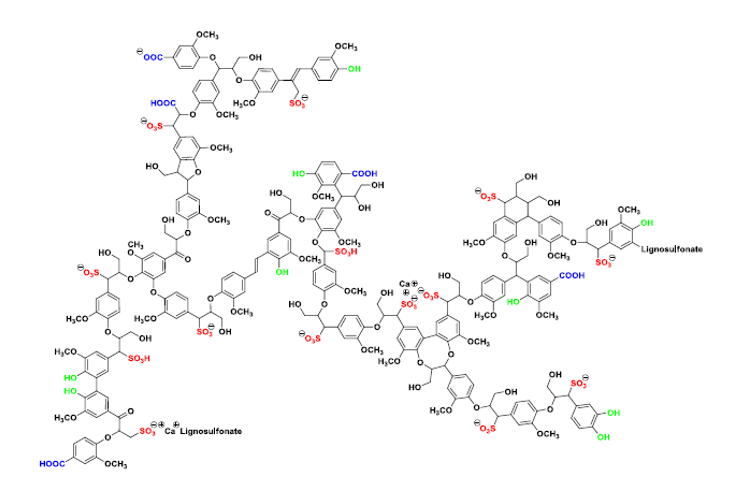

Chemical structure of lignin

The chemical structure of lignin, like that of many other natural polymers, is very complex. As lignin is normally insoluble in non-polar and organic solvents, a frequent method used to separate cellulose from lignin is to treat wood chips with a chemical solution at high temperatures. As a result, the basic component of the polymer, phenylpropane, is sulfonated and certain bonds between lignin and carbohydrates are broken down. The lignosulphonate obtained in this manner comprises polymers of varying weight, based on hydrolysis, the main components of which are calcium lignosulphonate and a number of polysaccharides.

Lignosulphonates can be polymerized, hydrolyzed, halogenated, nitrated, oxidized, dehydrogenated, or desulfonated. They can enter into mixed dimeric reactions with other functional groups for which they are excellent extenders. The polysaccharide groups can be oxidized, inverted, or eliminated by using molecular separation processes.

Lignin and the Environment

Lignins have been used for many years on road surfaces, in pesticide formulations, in animal feedstock, and other products that contact food. As a consequence, lignin manufacturers have performed extensive studies to test lignin’s impact on the environment. Results show that lignins are safe for the environment and not harmful to plants, animals, and aquatic life when properly manufactured and applied.

In the pulp mill process, cellulose is separated from lignin and recovered for use in a variety of different products. Lignosulfonate, a lignin product recovered from the sulfite pulping process, is of special interest in considering environmental issues. It has been used as a treatment for dirt roads in Europe and North America since the 1920s. Extensive scientific research and the historical use of this product without reported complaints of plant damage or serious problems support the conclusion that lignosulfonates are environmentally friendly and non-toxic.

Environmental studies on Lignosulfonates

A 1960 study at Industrial Bio-Test Laboratories to determine subacute and chronic toxicity from lignosulfonate noted no abnormalities in blood studies, urinalysis, food consumption, behavior, or autopsies of treated laboratory rats. Studies conducted at the WARF Institute in 1976 on sodium lignosulfonate again showed that product to be non-toxic in acute oral toxicity studies using white rats. In a 1986 study published in the International Journal of Environmental Studies, vegetation and growth of fir trees were not significantly affected at normal and above normal application rates of lignosulfonates.

Toxic levels of lignosulfonates in surface water have been established and confirm that concentrations must be relatively high before fish and other organisms are affected. A series of toxicological tests using laboratory animals were performed more recently (1988-1990) on lignosulfonates at Stanford Research Institute International in California. Careful analysis of the data confirmed earlier conclusions. Lignosulfonates were found to be essentially non-toxic and not irritating, not mutagenic or genotoxic, and safely used in animal and human food contact products. Lignosulfonates have been approved for use in animal feed, various food contact materials, and pesticide formulations by the U.S. Food and Drug Administration, the regulatory agency charged with ensuring the safety of the food supply. Lignosulfonates have been used for nearly 40 years in animal feed. No chronic toxicity problems have been recorded to date, either from applications involving human food contact or animal consumption.